About

The Geotechnical Centrifuge Facility (GCF) at The Hong Kong University of Science and Technology (HKUST) is a state-of-the-art laboratory that specialises in physical modeling for a wide range of geotechnical engineering problems related to sustainability for energy and the environment. The facility is adept at addressing geo-energy and geo-environment engineering problems and the complex soil-structure interaction challenges involved. Over the past decades, the technique of geotechnical centrifuge modeling has seen rapid development and gained global popularity. The essence of centrifuge modeling lies in its ability to replicate the stress conditions of full-scale constructions (prototypes) by using scaled-down models. This is achieved by applying enhanced body forces through centripetal acceleration, making the centrifuge an optimal tool for studying gravity and time-dependent geotechnical problems.

Partially funded by a UGC Central Allocation Vote, a RGC Collaborative Research Fund (Equipment) and supplemented by matching funds from HKUST, the GCF is unique within Hong Kong. Together, the drum and beam centrifuges at the HKUST form a comprehensive centrifuge cluster that is among the best in the world. This facility serves not only the university but also the broader geotechnical community locally and internationally.

The beam centrifuge is suitable for many applications such as slope stability and foundation modeling and this facility has a modeling capacity of up to 400g-ton. Geotechnical models can be constructed within boxes that measure up to 1.5m x 1.5m in plan and 1.0m in height. A number of novel and state-of-the-art tools and devices have been developed over years to facilitate the modelling of various geotechnical problems addressing the geo-energy and geo-environment challenges.

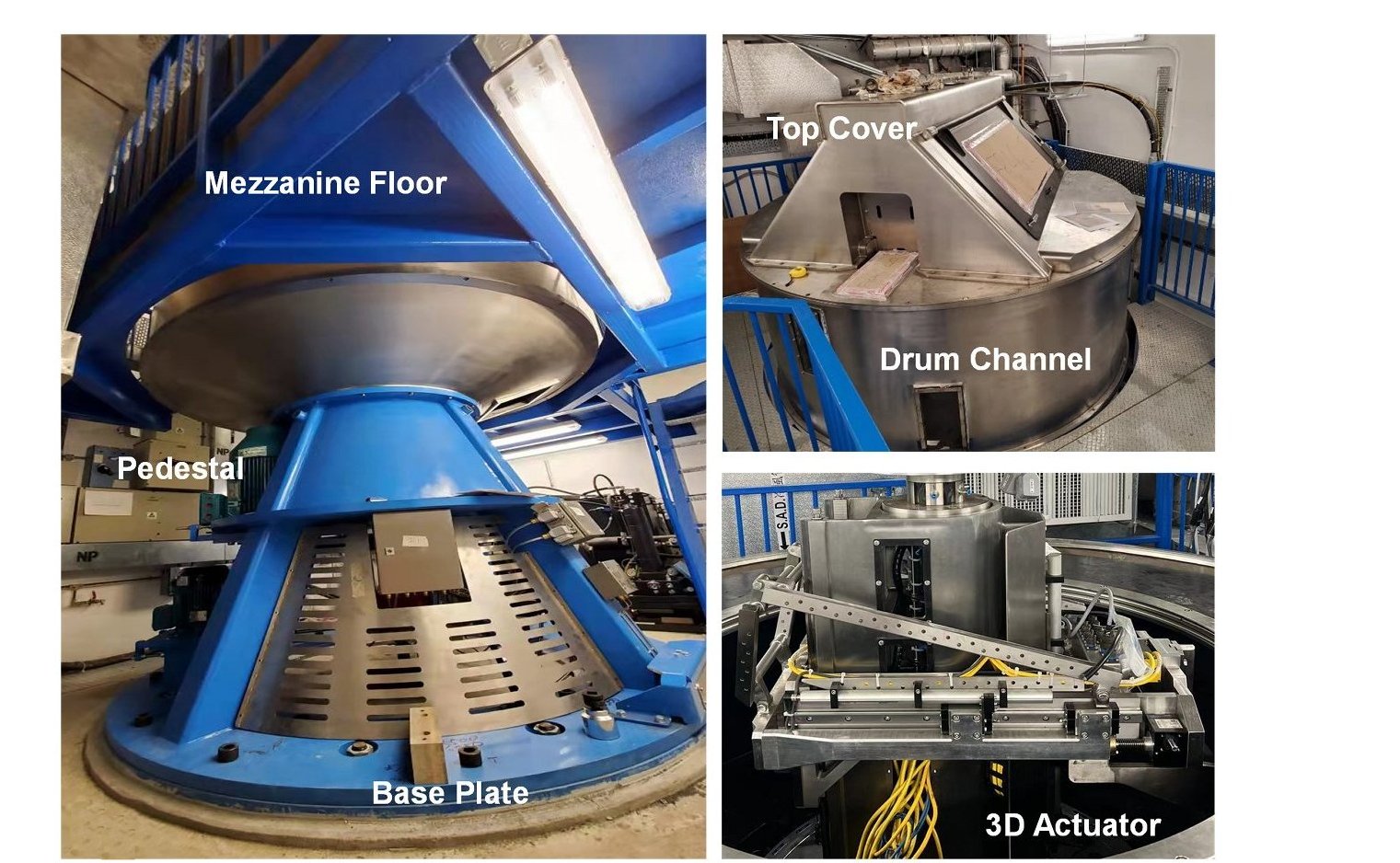

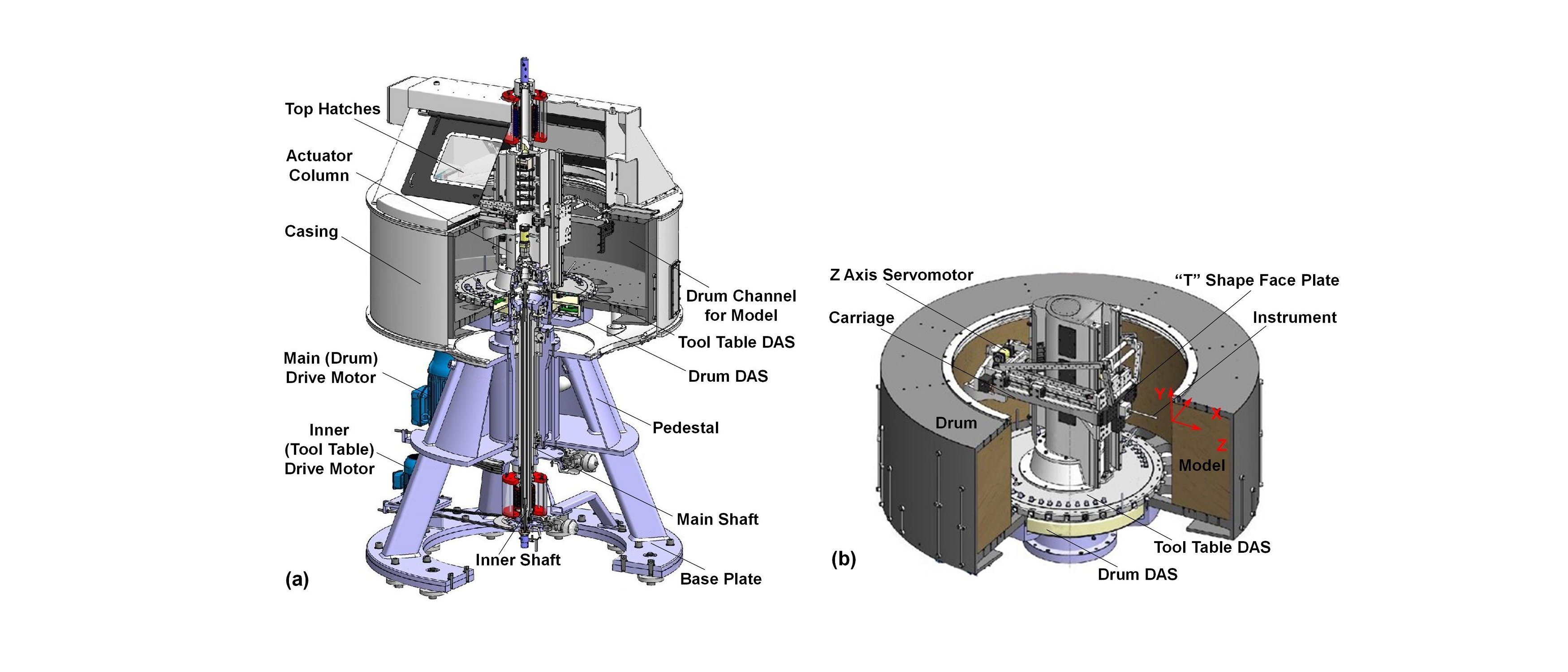

Complementary to the beam centrifuge, the modular drum centrifuge is suitable for applications involved long displacement or deformation, such as debris flows and sediment transport problems. This versatile drum centrifuge can be operated in two configurations: a drum environment and a beam environment. In the drum configuration, it can generate radial accelerations up to 250g for payloads as heavy as 3.48 ton, achieving a speed of up to 450 rotations per minute. The drum's testing channel measures 2.2 m in diameter, 0.7 m in width, and 6.91 m in length, which scales to 175 m wide and 1726 m long at prototype scale under 250g condition.

Most geotechnical structures are subject to combined vertical (V), horizontal (H) and moment (M) loadings, and the bearing capacity envelope can be described by a three-dimensional ellipsoid. Hence a multi-axis 3D loading actuator has been developed for the drum centrifuge facility. The actuator is attached to the top of the tool table, which is able to interact with the model in the drum channel by accurate positioning and load application in the X- (circumferential), Y- (vertical) and Z-(radial) directions. This feature is one of the uniqueness of the drum centrifuge at the HKUST.

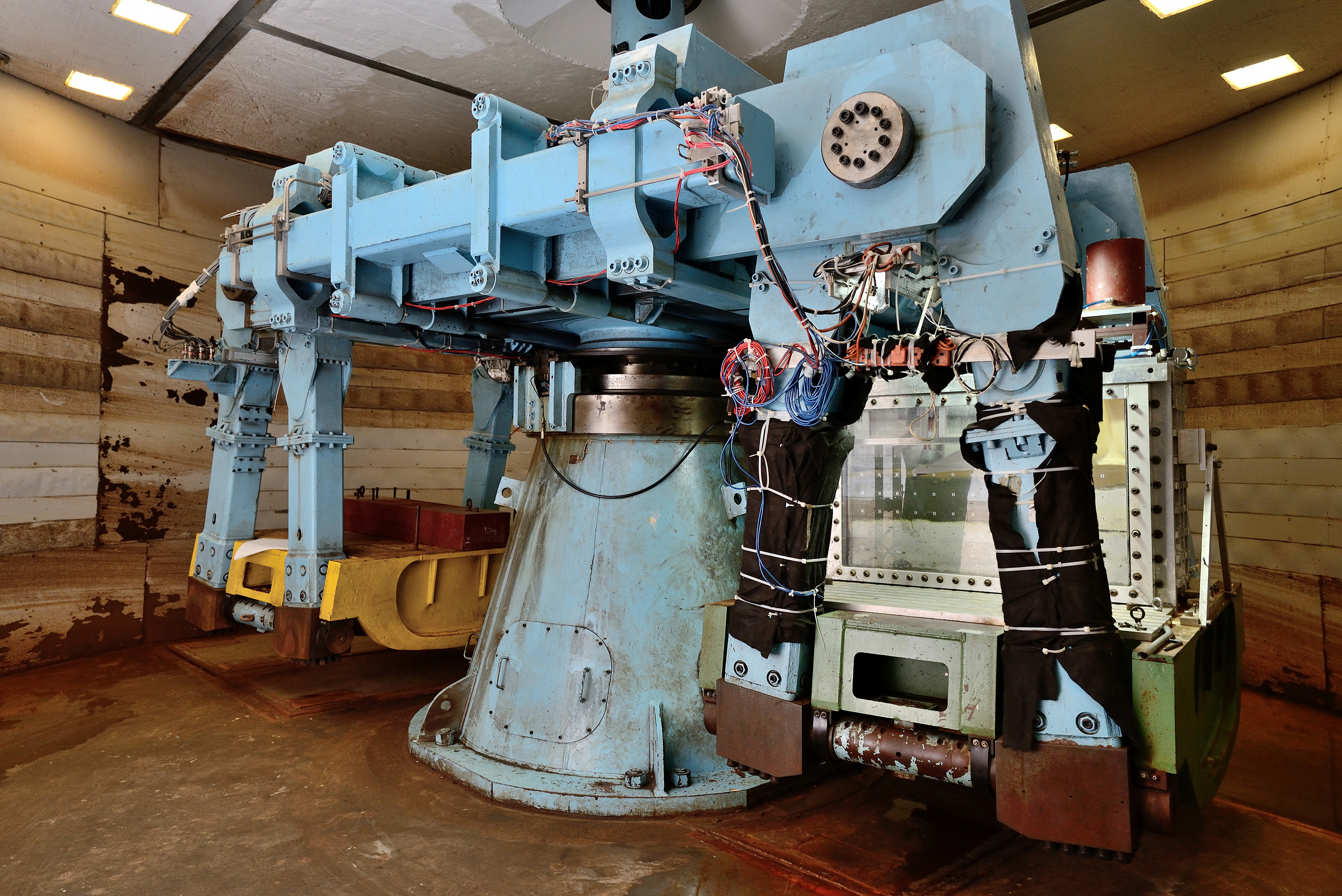

The 8.5 m-diameter (400g-ton) beam centrifuge at the HKUST

Drum centrifuge (picture)

Drum centrifuge (schematic)